Part 1: Beginner's Guide: Incubator Types & Uses

Pulished on Aug. 01, 2025

In the field of poultry farming, hatcheries, and aviculture, incubators play a crucial role in the successful hatching of eggs. They create artificial environments that mimic the natural conditions required for embryo development, ensuring a high hatching rate and healthy offspring. This article will delve into the types of incubators, their uses, and provide a comprehensive guide on how to choose the right one.

Setter incubators are designed for the early stage of egg incubation, focusing on providing optimal conditions for embryo development during the initial growth phases.

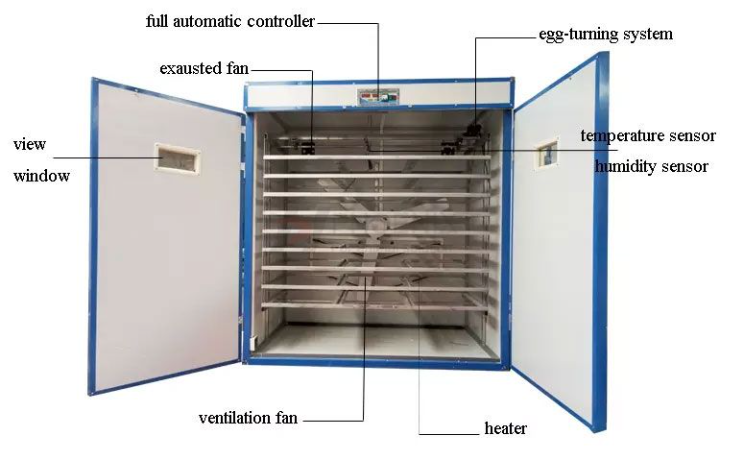

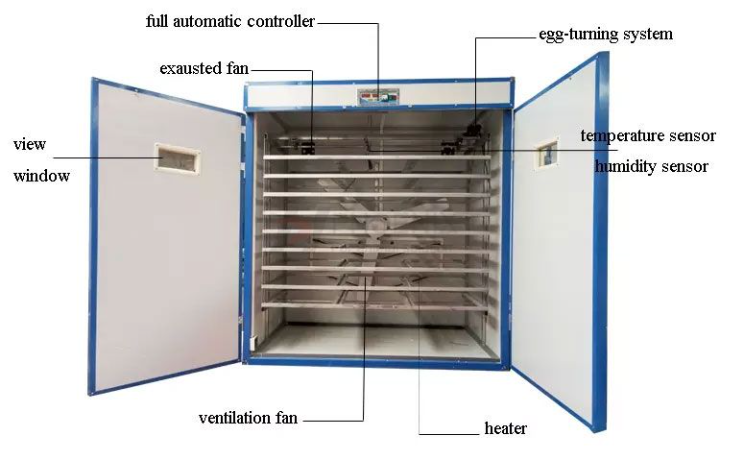

Function and Design

These incubators are engineered to precisely control temperature, humidity, and ventilation to support the critical processes of cell division and organ formation in the embryo. For example, in the case of chicken egg incubation, a setter incubator maintains a relatively stable temperature, often around 37.5 - 38.5°C in the early days, along with appropriate humidity levels (usually 40 - 60% for chicken eggs initially).

The internal structure is typically designed to hold egg trays securely, allowing for uniform distribution of heat and air. Some advanced setter incubators also have systems for automatic egg turning, which is essential to prevent embryo adhesion to the eggshell and ensure even development. The turning frequency is usually set at intervals, such as every 2 hours, with a turning angle that can range from 45° to 90° depending on the egg type.

Limitations in the Hatching Process

A key characteristic of setter incubators is that they are not intended for the final hatching stage. As the embryos approach the hatching phase (for chicken eggs, around day 18 - 19), the eggs need to be transferred to a hatcher incubator. This is because the internal environment of a setter, including space and air circulation patterns, is not optimized for the newly hatched chicks. The lack of proper space for the chicks to move and the potential build - up of harmful gases if chicks stay too long are among the reasons for this transfer requirement.

This type of incubator combines the functions of both the setter and the hatcher, providing a seamless process from egg to hatched chick.

Integrated Functionality

It can be programmed to adjust environmental conditions as the eggs progress from the early incubation stage to the hatching stage. In the early days, it acts like a setter, maintaining the right temperature, humidity, and egg - turning patterns for embryo development. As the hatching time approaches, it modifies these conditions to suit the hatching process. For instance, the humidity may be increased slightly to around 65 - 70% for chicken eggs during hatching to facilitate chick emergence, and the temperature may be adjusted to a more suitable level for the newly hatched chicks, which is usually a bit lower than the peak incubation temperature, say around 37°C.

The internal design also accommodates the change from holding eggs to providing a space for the newly hatched chicks. There is enough room for the chicks to move around without being cramped, and the air circulation is designed to remove harmful gases like carbon dioxide efficiently while supplying fresh oxygen.

Advantages in the Hatching Process

One of the main advantages is the convenience it offers. Poultry farmers or aviculturists do not need to transfer eggs between different machines, reducing the risk of egg damage during transfer. Also, it provides a more controlled environment for the chicks in the initial hours after hatching. The chicks can stay in the machine for a short period (usually a few hours to a day) until their down is dry and they are more active, which helps in their initial adaptation before being moved to a separate rearing area. However, it should be noted that even with this type of incubator, long - term housing of chicks (more than a day or two) is not advisable as the internal space is still limited compared to proper rearing facilities, and factors like waste accumulation can affect the health of the chicks.

Commercial Chicken Production

In large - scale chicken farms, incubators are indispensable. They allow for the mass production of chicks with a high degree of control over the hatching process. By using incubators, farmers can ensure a consistent supply of day - old chicks, which is crucial for maintaining a regular production cycle. For example, a commercial poultry operation may use large setter - and - hatchery machines to hatch thousands of chicken eggs at once. This not only increases efficiency but also enables better management of the flock, as the chicks can be hatched in batches according to market demand.

Incubators also help in improving the quality of the chicks. By providing optimal environmental conditions during incubation, the chances of producing healthy, vigorous chicks are significantly increased. This, in turn, leads to better growth rates, higher feed conversion efficiency, and ultimately, more profitable poultry production.

Duck, Goose, and Other Poultry

For other poultry species like ducks and geese, incubators are also widely used. Although the incubation parameters (such as temperature and humidity) may differ from those for chickens, the basic principle is the same. Duck eggs, for example, require a slightly lower incubation temperature (around 37 - 37.5°C) and higher humidity in some stages compared to chicken eggs. Incubators can be adjusted to meet these specific requirements, allowing for successful hatching of ducklings and goslings. This is important for both commercial production of these poultry species for meat, eggs, or down, as well as for small - scale or hobby - based breeding.

Breeding of Pet and Exotic Birds

In aviculture, incubators are used to breed a variety of pet birds such as parrots, finches, and canaries, as well as exotic bird species. Many of these bird species have specific incubation needs that can be met by incubators. For example, some parrot eggs may require very precise temperature control, often within a narrow range of 37 - 37.2°C, and specific humidity levels. Incubators allow aviculturists to replicate these conditions, even in environments that are not naturally suitable for bird breeding. This has enabled the successful breeding of rare and endangered bird species in conservation projects, as well as the production of pet birds with desirable traits.

Incubators also play a role in hand - rearing birds. When eggs are hatched in an incubator, the newly hatched chicks can be hand - fed and raised, which is important for taming pet birds and ensuring their socialization with humans. This is especially relevant for species that may be difficult to raise by their parents in captivity.

Scientific Research

In biological research, incubators are used to study embryo development in birds. Researchers can control the environmental conditions precisely to investigate the effects of different factors on embryo growth. For example, by varying the temperature, humidity, or oxygen levels in an incubator, scientists can study how these changes impact the development of different organs in the embryo, the hatching success rate, and the long - term health of the hatched chicks. This research is valuable for understanding basic avian biology, as well as for developing better breeding and conservation strategies.

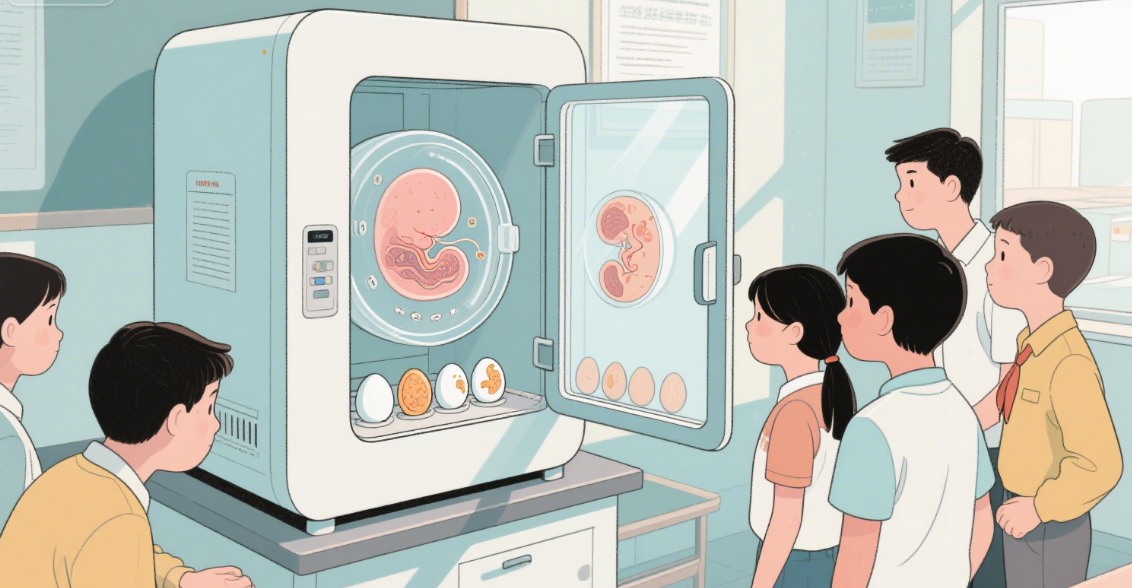

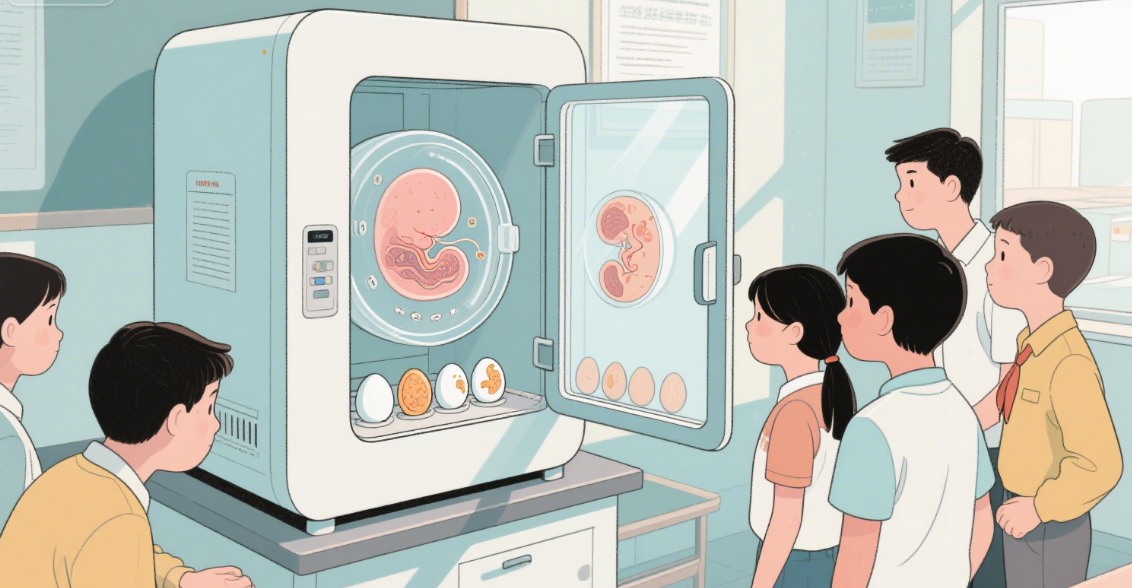

Educational Purposes

In schools and universities, incubators are used as educational tools. They provide students with a hands - on experience of the egg - hatching process, allowing them to learn about avian reproduction, embryo development, and the importance of environmental factors in the life cycle of birds. Students can monitor the changes in the eggs during incubation, observe the hatching process, and learn about the care of newly hatched chicks. This practical learning experience enhances their understanding of biological concepts and can inspire interest in fields such as zoology, agriculture, and environmental science.

View More information about chicken farm

View our Youtube More breeding equipment video

Phoenix Breeding Equipment: 19+ years of breeding equipment production and export experience. As a result of our high-quality products and outstanding customer service, we have gained a global sales network reaching Europe, North America, Southeast Asia, Africa, South America, etc. Successfully in use on both family-owned farms and large farm complexes. Providing individual and automatic equipment to feed your livestock: chicken drinking line, chicken feeding line, poultry drinker and feeder, exhaust/ventilation fans, egg Incubator, and so on breeding equipment.

CONTACT US

Phone:+86 19061974162

Email: sales@goldphoenixa.com